What is scaffolding?

The temporary framework (either timber or steel) having platforms at different level which enables masons to sit and carry on construction work at different height of building is defined as scaffolding. Scaffolding is needed for masons to sit and place construction materials when the height of wall, column or any other structural members of a building exceed 1.5m. It provides a temporary and a safe working platform for various types of work as: construction, maintenance, repair, access, inspection, etc.

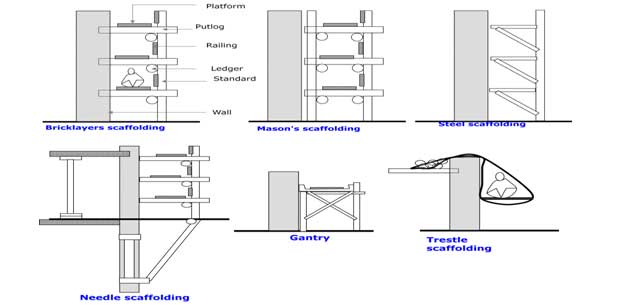

Parts of Scaffolding:

Standards: Standards refer to the vertical member of the frame work that is supported on the ground.

Ledgers: Ledgers are the horizontal members running parallel to the wall.

Braces: Braces are diagonal members running or fixed on the standard to provide stiffness to the scaffolding.

Put Logs: Put logs refer to the transverse members, placed at right angle to the wall, one end supported on ledgers and the other end on the wall.

Transoms: When both the ends of put logs are supported on ledgers, then they are said transoms.

Boarding: Boarding are horizontal platform to support workmen and materials which are supported on the put log.

Guard Rail: Guard rails are provided at the working level like a ledger.

Toe Board: Toe boards are boards placed parallel to ledgers, supported on put log to provide protection at the level of working platform.

Classification of Scaffolding

Scaffolding can be classified into various types which are listed below:

Single Scaffolding or Brick Layers Scaffolding

Single scaffolding is widely used for brick masonry works. This type of scaffolding consist of a single framework of standards, putlogs, ledgers, etc. Standards are placed at a distance of about 1.2m from the wall at 2-2.5 m interval and are connected by ledgers at a vertical interval of 1.2 to 1.5m. Putlogs are kept with one end on the ledgers and the other end in the hole left in the wall at an interval of 1.2 to 1.5m.

Double Scaffolding

Double scaffolding is widely used for stone masonry works. Provision of holes to support putlogs is difficult, so double scaffolding is preferred consisting of two rows of standards separated by ledgers. The first row of the scaffolding is placed at 20-30 cm away from the wall and the next row is kept 1m away from the first row. Transoms are placed on the ledgers and the cross braces in the scaffolding helps to make them more strong and durable.

Steel Scaffolding

Steel scaffolding is similar to mason scaffolding. It consist of steel tubes instead of wooden members. In such scaffolding, standards are placed at a space of 3m and are connected with the help of steel tube ledgers at a vertical interval of 1.8m.

Steel scaffolding consist of:

- Steel tubes 1.5 inch to 2.5 inch diameter.

- Coupler or clamps to hold pipe in different positions.

- Prop nuts to hold single pipe.

- Bolts, nuts and washers.

- Wedge and Clips.

Advantages of Steel scaffolding:

- Can be used for larger heights.

- Durable and Strong.

- Can be assembled easily.

- Higher fire resistance.

Disadvantages of Steel scaffolding:

- Higher initial cost.

- Skilled labor is required.

- Periodical painting is necessary.

Needle or Cantilever Scaffolding

Needle scaffolding may be single type or double type. In single type needle scaffolding, the standards are supported on series of needles whereas, in the double type, the needle and projecting beams are strutted into the floor through the openings. Needle scaffolding is used in the following cases:

- When hard firm ground is not available.

- When construction is to be carried on busy streets.

- When construction is to be carried on large height of a multi-storied building.

Trestle scaffolding

Trestle scaffolding are widely used for minor repairs or painting works inside the rooms. Trestle scaffolding consist of working platforms supported on movable ladders with no standards, putlogs, etc. These type of scaffolding can be easily shifted from one place to another.

Suspended scaffolding

Suspended scaffolding are mostly used for maintenance works as painting, pointing, distempering, white washing etc. It consist of a working platform suspended from the roof or parapet walls by means of ropes, wires or chains which can be raised or lowered at any desired level.